EPDM adhesive is a product specially designed to ensure a durable, flexible and highly resistant bond between EPDM (ethylene-propylene-diene monomer) membranes and a wide variety of surfaces. It is ideal for waterproofing systems, sealing roofs, terraces, water tanks, ponds and other construction projects that require maximum watertightness and resistance to the most demanding environmental conditions.

This adhesive interacts with the chemical structure of the EPDM, achieving a bond that combines mechanical and chemical resistance. It ensures that the membrane maintains all its functional properties over time, even in the face of structural movements, expansion or contraction of the underlying materials.

Its formulation offers key advantages over other conventional bonding products. It stands out for its high resistance to oxidation, ozone and ultraviolet radiation, as well as its ability to withstand rain, snow, hail and sudden changes in temperature. In addition, it maintains its elasticity permanently, allowing EPDM sheets to adapt to structural movements without the risk of detachment or cracking.

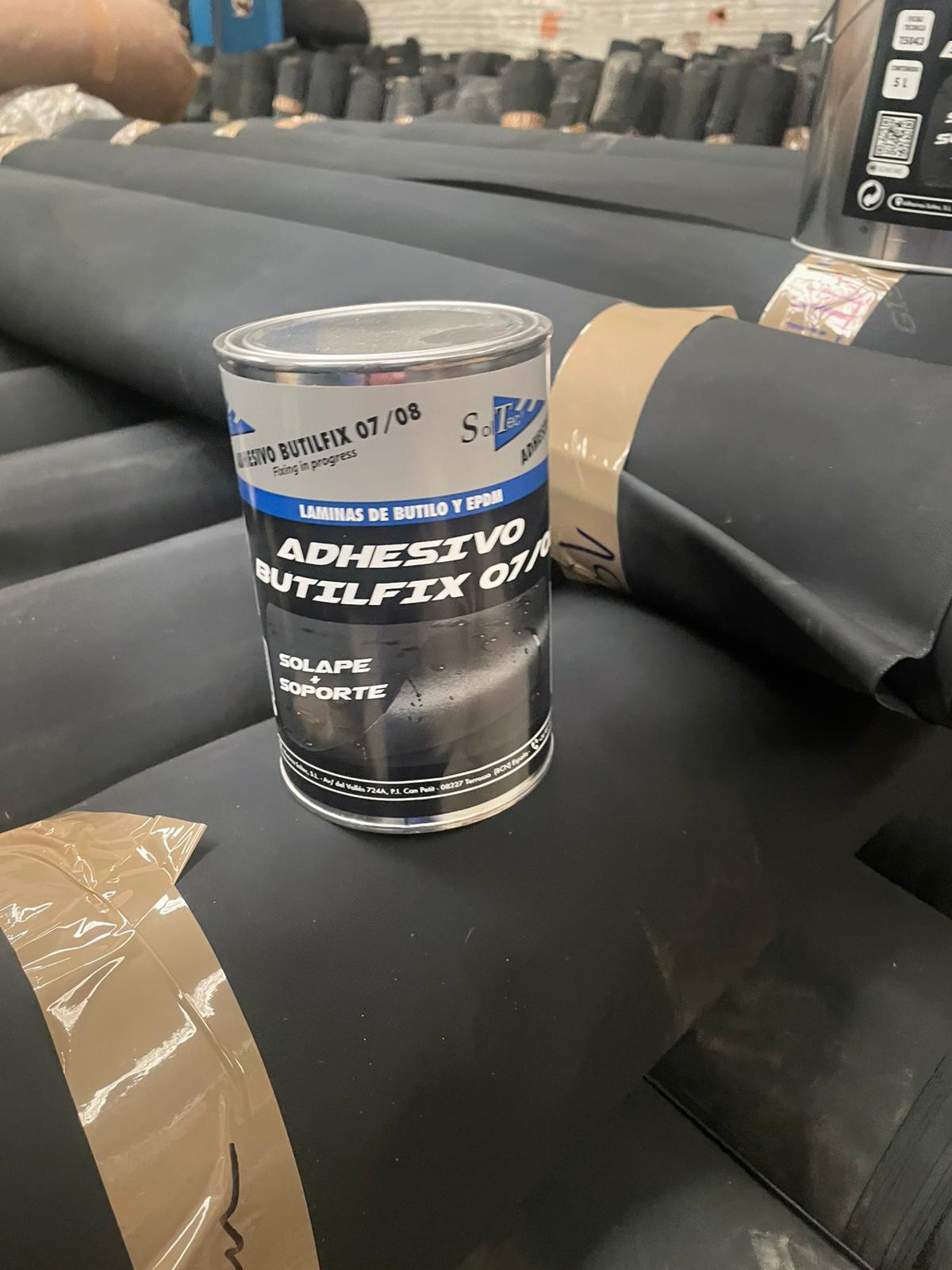

The EPDM adhesive is completely compatible with rubber, avoiding any type of degradation or alteration of the material. Its application is simple and versatile, available in liquid format and can be applied by roller, brush or spatula. Once applied, it achieves a fast and secure fixation, optimising installation times.

It adheres effectively to many surfaces, including concrete, mortar, treated wood, metal and thermal insulation. It is also compatible with weathered asphalt and possesses chemical resistance to aqueous solutions, salts, weak acids and detergents. This makes it reliable in environments exposed to chemical agents or demanding environmental conditions.

One of its main advantages over traditional fastening methods is that it does not require nails, screws or anchors. This avoids compromising the integrity of the membrane and ensures a uniform and aesthetically clean finish. It allows large areas to be covered without discontinuities, guaranteeing continuous and effective waterproofing.

Maintenance of systems bonded with this adhesive is significantly reduced. Risks of peeling, leaks or premature deterioration are minimised, prolonging the life of the system. In addition, its rapid application saves time and labour costs, especially on large-scale projects.

This adhesive is used in a wide range of applications, both in new construction and in the refurbishment of existing structures. It is ideal on flat or pitched roofs, where EPDM membranes need to be fixed securely and reliably. On terraces, balconies and roof terraces, it protects against water and moisture seepage, preventing damage to the underlying structure.

In landscaping projects, it ensures the watertightness of decorative ponds, artificial ponds and fountains, keeping water contained without risk of leakage. It is also perfect for tanks, reservoirs and liquid storage systems, guaranteeing a reliable seal even under pressure or prolonged contact with water.

In drainage systems, channels and gutters, it provides additional protection against erosion, infiltration or damage caused by continuous exposure to water. Even in foundations, buried walls or underground structures, it protects against rising damp, lateral seepage and other problems resulting from prolonged contact with the ground.

For an optimum result, it is essential to prepare the surface correctly. It must be clean, dry and free of dust, grease, oil or loose particles. On porous or very absorbent surfaces, it is recommended to apply a primer beforehand to ensure maximum adhesion.

The adhesive is applied evenly to both surfaces to be bonded, allowing the solvent to partially evaporate until the coating is tacky to the touch. The membrane is then pressed firmly against the substrate, ensuring full contact. A pressure roller is recommended to eliminate air pockets and achieve maximum coverage.

Application should be carried out in dry conditions, with temperatures between +5 °C and +35 °C, avoiding excessive humidity, rain or fog during the initial drying time. Some adhesives contain flammable solvents and should be kept away from sources of heat or flame.

The use of gloves and protective goggles is recommended, as well as ensuring adequate ventilation in enclosed spaces. Containers should be stored tightly closed, in cool and dry places, protected from direct sunlight and extreme temperatures. Shelf life can be extended up to 12 months if stored properly, while once opened it should be used as soon as possible.

The average yield varies depending on the surface and method of application, but generally between 0.25 and 0.40 litres per square metre is required. A 10 litre container can cover between 25 and 40 m² of EPDM membrane, allowing you to plan the amount of material required accurately and optimise your investment.

This adhesive provides clean and aesthetically pleasing installations without compromising waterproofing. It significantly reduces application time thanks to its fast setting and offers flexibility to adapt to structure movements without compromising adhesion and waterproofing.

Its compatibility with multiple substrates makes it extremely versatile and suitable for different types of construction, from housing to large commercial or industrial projects. Its strength, flexibility, ease of use and compatibility with different materials make it a superior option to traditional fixing methods.

In conclusion, EPDM adhesive ensures the quality and durability of modern waterproofing systems. It guarantees the integrity of membranes, prevents leaks and protects structures for decades. Thanks to its advanced formulation and unique properties, it is positioned as an indispensable product for professionals looking for quality, durability and efficiency in their construction projects.

Adhesive characteristics:

-

Liquid adhesive specially formulated for EPDM.

-

High adhesion and compatibility with EPDM membranes.

-

Flexible and elastic, it maintains its properties in the face of structural movements.

-

Resistant to UV, ozone, water, temperature changes and mild chemicals.

-

Applicable on concrete, metal, treated wood, etc.

-

Does not require mechanical fixing, avoids punctures and damage to the membrane.

-

Fast drying, easy to apply by brush, roller or spatula.

-

It allows continuous and durable waterproofing, without cracks or detachments.